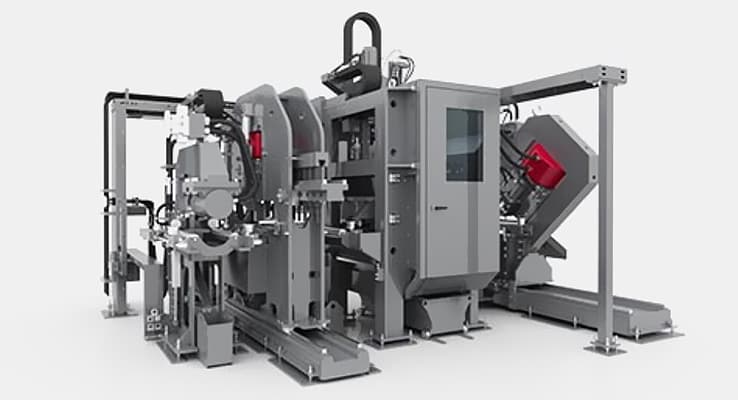

Beam Layout Welding Utility

The clamps are released and the web is transferred to the tacking fixture. The welding equipment includes a flux hopper, travel carriage and controls. It also has a 1,000 Amp power supply. Full-color laser projectors will show all information needed to accurately tack-weld connections onto the beam or other connections.

.jpg)